Take advantage of all the benefits of transfer printing

With transfer printing, you can make various types of printed products faster, more flexibly and much more cheaply than with conventional screen printing. There is little difference in quality. How is that possible? We prepare prints on iron-on foils for textiles, or on transfer paper, but it is up to you to apply them. This allows you to:

Significantly reduce the cost of printed textiles

Print on textiles flexibly in line with your current needs and requirements – it takes a few minutes to apply the print

Save on storage space – you only store the transfer prints, not printed textiles

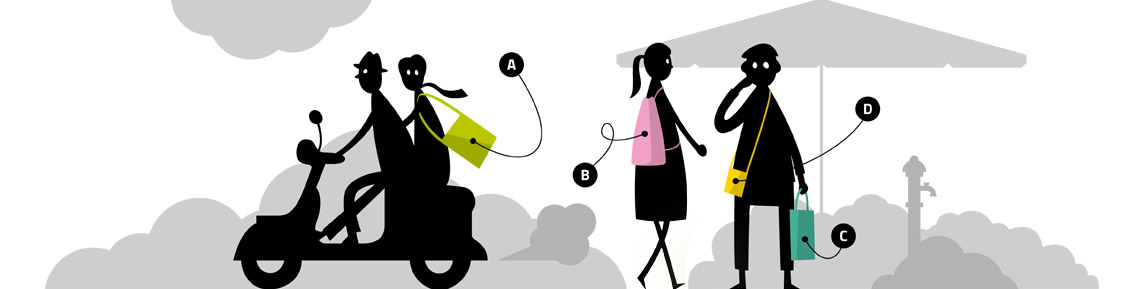

Print on products for which direct textile printing cannot be used – you can print on backpacks, bum bags, key rings, bicycle bags and other products

If you need to print individual names, for example, on sports T-shirts, transfer printing is a must

Screen print transfers

The quality of transfer printing is comparable to spot colour printing. The transfers we supply are colour-fast, resistant to abrasion and do not wash off easily. There is a slight disadvantage in that printing on larger areas of coloured fabrics is not so breathable, but this is of little significance for most printed products. Minimum run of 10 transfer sheets.

Digital transfer printing

Technology suitable for printing full-colour raster photos and for printing that involves colour transitions. A digital transfer meets all printing standards. There is a slight disadvantage in that printing on larger areas of coloured fabrics is not so breathable. Digital transfers can only be applied to cotton fabrics. Minimum run of 10 transfer sheets.

Data for the production of transfers

It is best to send templates for transfer printing in the vectors cdr, ai, eps, or pdf. Convert text to curves. If you only have raster templates, we recommend approx. 300 dpi as the optimal resolution for printing. If you require an exact colour scheme for your printing, enter the colours according to their Pantone C classification. Colours entered in RGB and CMYK mode are converted to the closest Pantone C colour. It is possible to print even very fine designs with lines from 0.2 mm and small text.

Data for the production of digital transfers

Templates for digital transfers may be raster designs with smooth colour transitions. It is best to send data in psd format on a transparent background, in CMYK mode, with a resolution of approx. 300 dpi. For printing on coloured fabrics, digital transfer does not allow the design to “fade out” – the edge of the design must be precisely framed. The maximum print format is 29 × 42 cm.

Transfer printing formats

The print size depends on the size of the transfer sheets. We print in 23 × 33.5 cm format as standard. If larger designs are required, we can print up to a format of 30 × 43 cm. You can include multiple designs in the print format. Maintain a minimum distance of 10 mm between each design. Alternatively, send the designs separately (along with the size and number of units required) and we will make all the preparations.

Applying transfer printing to polyester fabrics

Let us know if you will be pressing transfers on polyester, nylon or blended fabrics. In any of these cases, we will also print a blocking colour to prevent the dye from sublimating from the textile into the printing inks.

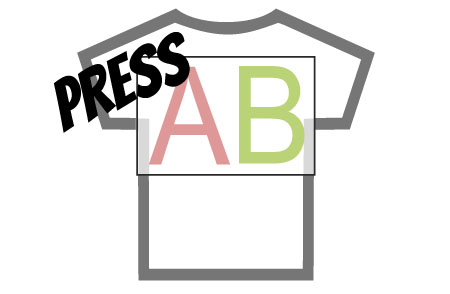

Transfer printing – press specifications

Temperature: 160 °C, pressure: 0.5-0.7 Mps (5 to 7 bar), time: 7 to 15 seconds

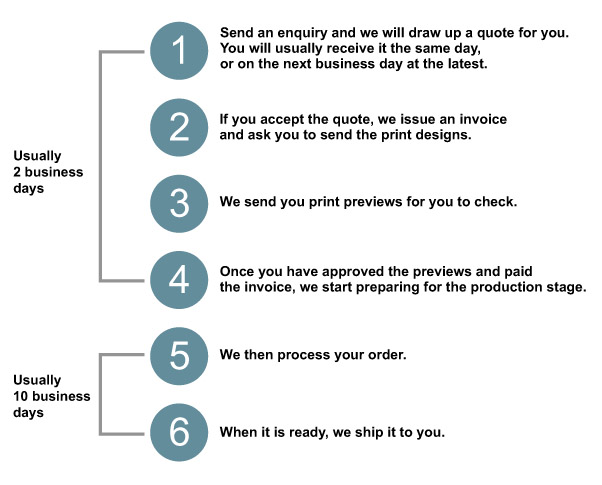

Submit an enquiry for transfer foils

Preview the design you need to print.

Specify the size of the design and the number of units.

Specify the material and colours of the textile on to which the transfers are to be applied.

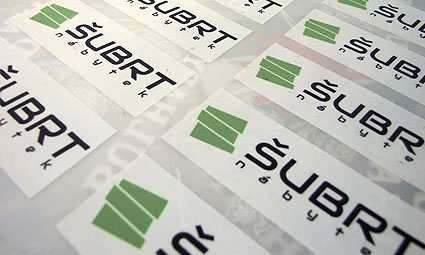

Examples of transfer foils for textiles

(+420)

(+420)